Research Center

Constructing production capacity that meets customer demands

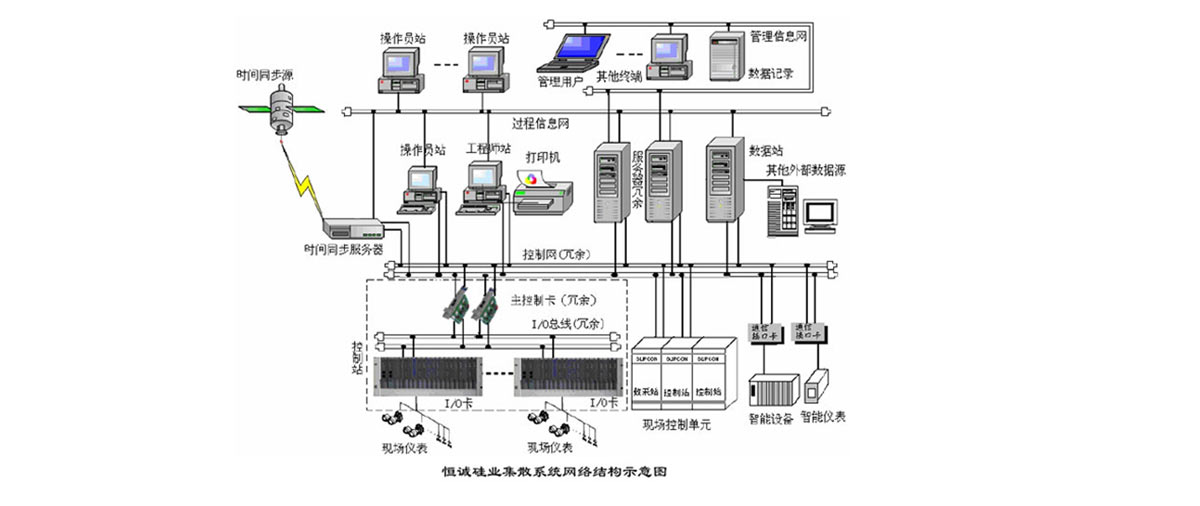

Wuxi Hengcheng Silicon Industry Co., Ltd, relying on the distributed control system(DCS), has built up intelligent high dispersion silica(HDS) plants. The number of intelligent producing equipment, instruments and testing devices takes up more than 90% of the total production equipment. Based on automation and information techniques, these plants have realized interconnecting and interworking through a series of methods such as information exchange, sensing analysis, advanced control, real time optimization and information module. The plants can collect and analyze basic information about products, operation and equipment status so as to achieve quick response in production, which well promotes the production flexibility to meet customized requirements.

Intelligent plants can closely integrate production management with operation system. They can realize data transmitting, collecting, processing, storing, utilizing and administration in each link of the production management. A unified production management platform has been set up which enjoys comprehensive functions such as producing directing, process controlling, quality assessing, equipment monitoring & supporting, abnormality early warning & detecting, trace analyzing, performance evaluating and decision judging. It helps to achieve digital & intelligent management of the company’s producing process, increase company’s productivity while guarantee production quality, reduce production cost and reinforce our products competitiveness.

Intelligent plants can efficiently implement production organizing, controlling and recording. After the production task, formulation, technique requirements and parameters have been input into the DCS, the operator will carry out accurate producing as per to the directions. All the technique parameters generated in the production process will be recorded in the DCS in real time for necessary tracing. Consequently products in our plants are reproducible, as different operators, when choosing the same parameters, can produce products with the same quality. In addition, the intelligent plants also adopt automatic packaging system without any manual intervention.

The intelligence and automation of production; the combination of information and material flow; the integration of R&D and manufacturing, production and management, business and finance… All these have actualized the linking between production and marketing; realized the integration of management and control; and promoted the production and operation efficiency which can reduce costs and control risks. At the same time, Hengcheng has built up “garden-like” factories that provides great working environment and ensures the safety and health of all employees.

Merits of Intelligent Plants:

Intelligent Equipment

It is the basis for the building of intelligent plants. The equipment includes mechanical equipment, instruments and testing devices, and the intelligence does not merely refer to that of individual equipment, but of the whole production line. The equipment is being monitored for relevant control, and the environment is also being supervised for timely adjustment.

Accurate Data

The reliability of the data in management information system, the efficient and accurate data collection, the distant data maintenance and centralized management, the recording of production data… all these are the keys to the establishment of intelligent plants, and they are the evidence of production process. They ensure timely data obtain for statistics & analysis as well as for data saving.

Lean Production

The production sites are in real time supervision, and the working procedures are interconnected where timely communication and contact between different production posts guarantees the stability of the production line. The lean production requires the following operations: be accurate and efficient to promote work capacity; take partition stock and update the inventory dynamic data in time; carry out positioning management for in-warehouse and ex- warehouse to avoid human error.

Integrated System